High-Precision Detection of Soldering Defects and Component Misalignment – Case Study of PCB Assembly Inspection

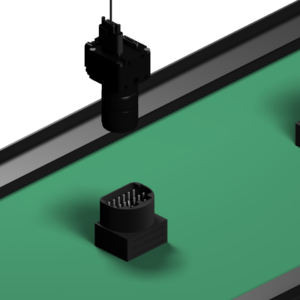

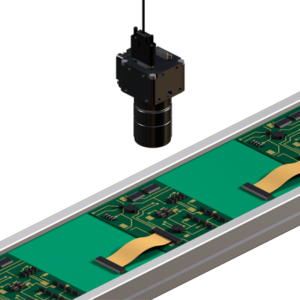

n the PCB assembly process, which directly affects the reliability of electronic devices, it is essential to reliably detect even minute solder cracks, lifted components, or misaligned placements.

OMRON SENTECH industrial cameras, equipped with high-resolution CMOS sensors and global shutter technology, capture fine details with clarity. They also support high-speed interfaces such as GigE Vision and USB3 Vision, enabling real-time inspection that keeps pace with high-speed production lines.

This implementation helps prevent defective products from leaving the line, while significantly contributing to improved product quality and manufacturing efficiency of electronic devices.

Contact

For any questions about our products and services,

including specifications and technical support, please feel free to contact us.

Headquarters,

Sales Department+81 46236-6660

Newsletter Subscription

Stay up-to-date with our latest news, including new product releases,

information on discontinued products, and upcoming trade shows.